Following on from our blog on Abt #5’s damaged connecting rod and expansion link last year, we’re pleased to announce her return to passenger services in January 2022.

A reminder? Sure…

The connecting rod ‘connects’ the piston in the cylinder and provides the motion that drives the pinion (or, in the adhesion engines, provides the motion to the wheels). The movement converts the reciprocating motion of the piston into the rotative motion of the pinion. There’s a lot of pressure during this process and, in October last year, one of these rods snapped, also causing damage to the expansion link and return crank.

The Abt locomotives are fitted with four engines – two on the outside to drive the adhesion wheels, and two on the inside to drive the pinion that engages with the rack between Hall’s Creek and Dubbil Barril. Because we operate a narrow-gauge railway, there’s only 1067mm between the wheels, which means there’s not a lot of room inside to squeeze two engines and all the valve gear. To save space, the more standard style of Walschaert’s valve gear has been modified to fit, which means the rack engine connecting rods are a little different to the adhesion ones.

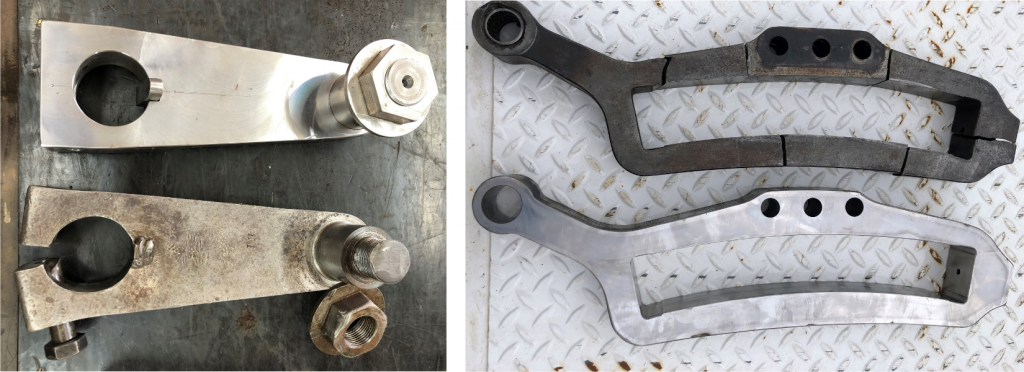

To reduce the chance of a failure also occurring in the other rack engine connecting rod on Abt #5, the Engineering Company in West Somerset (Tasmania) manufactured two new connecting rods, replacement expansion link and return crank. Since then, our workshop team have fitted the new parts to the locomotive and run Abt #5 through trial steaming sessions at Carswell Park in Queenstown, before heading out onto the rack for further testing. Our engineering staff are also reviewing the designs and seeking a way to improve the strength of the connecting rods on all the Abt locomotives for the future.

Having passed her tests with flying colours, Abt #5 has now returned to passenger service. Welcome back Abt #5!